ENTREPRENEURSHIP

Why you should buy a burn table

Sheet goods, such as plastics, metals, wood, and many more are the materials used in manufacturing to produce a wide range of parts. These materials can form the inputs you need for more complex processes that may shape blanks into three-dimensional form. For instance, in the automotive industry, plate and sheet steel can be stamped into blanks utilizing presses as well as custom-made tooling.

Unfortunately, you need a significant investment to create the tool die for these processes. The good news is that there are several other ways you can use to cut sheet and plate materials. And, CNC processes provide a significant benefit over machines, which need tooling as they can cut anything described by the program. Remember that you need to buy a burn table to cut sheet and plate materials using CNC laser, plasma cutting, and many more. This article discusses why you should buy a burn table.

CNC laser and plasma cutting

There are some differences between laser and plasma cutting. The main thing you should consider is the material you want to cut. It’s worth noting that plasma cutting can be utilized on conductive materials and laser processes usually cut a variety of materials, such as textiles, plastics, and wood. But since a laser cutting machine utilizes a focused beam of light designed to burn through the material, it can sometimes not be effective on highly reflective materials like copper.

Besides, some laser machines cannot cut materials that are thicker than 3/4 of an inch, but this is changing as the technology develops. A plasma machine cuts metal plates with thickness of up to an inch and a half.

The accuracy of the cut also varies between the two processes. For example, laser cutting can lead to a small kerf and has a high accuracy. The parts are dimensional and are similar to drawing specifications. On the other hand, a plasma torch leaves a kerf that is wider and there are more spatters, slag, and dross on the part, which can need post-processing for cleanup.

Another thing worth considering between the two processes is the heat deformation. Laser cutting can cause little deformation, especially in thin materials. But plasma cutting causes a huge deformation because there is intense heat that is similar to welding processes.

You should remember that with laser cutting, there is a beam of photons that come at a specific wavelength fired at your work piece together with high-pressure gas like nitrogen. This intense beam can melt, vaporize, and ablate the material. But the laser can be directed by G-code that guides the cutting edge to your work piece, which can be positioned horizontally on your cutting table.

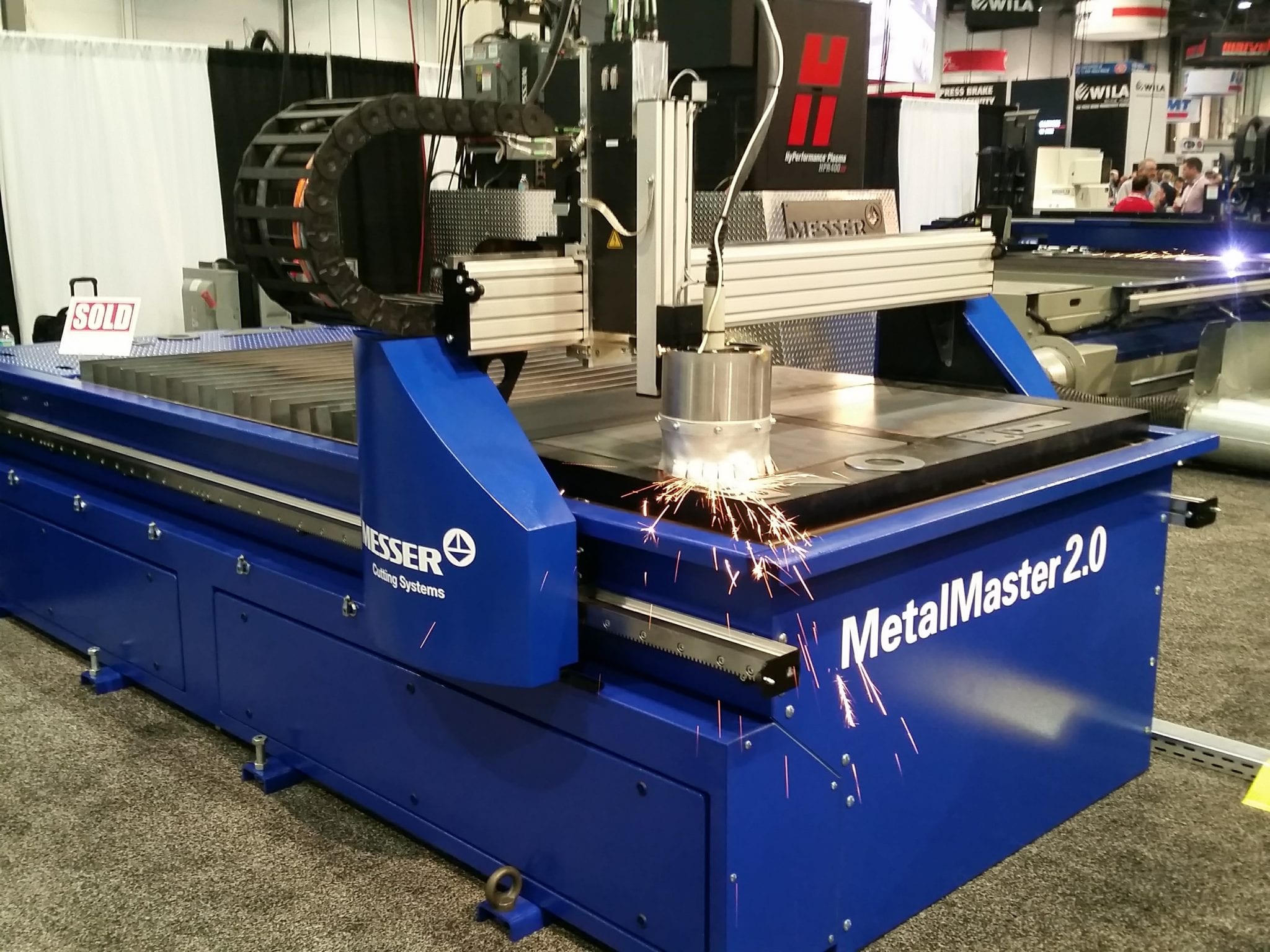

A burn table

The plasma burning table also called the plasma cutting table is broadly used because it’s a versatile and efficient tool. You can use it to cut thick and heavyweight materials pretty quickly. A CNC plasma cutting table can cut materials of different types of construction and manufacturing applications. A plasma cutting machine is computer automated, so this allows it to have a high level of accuracy for a precise cut.

This cutting table is utilized in the metal cutting processes. Some industries that use it include the engineering, agriculture, manufacturing, and construction industries. No doubt, a CNC plasma cutting table can help the way you cut metals.

It’s worth mentioning that plasma cutting is a standard method that is utilized by various industries to cut stainless steel, aluminum, iron, and other metals by using a plasma torch. A plasma cutter can function by sending an electric arc via a gas that passes through a small opening. This gas can be nitrogen, shop air, oxygen, argon, and many more. This increases the temperature of the gas to a fourth state of matter. Remember that matter has three states, which are a gas, liquid, and solid state, but scientists consider plasma as the 4th state. Matter tends to change from one state to another by introducing energy like heat.

Simply put, gas can be blown at high speeds through a nozzle and an electrical arc melts the element. The compressed air is used to blow the molten element. Plasma cutting tables are commonly utilized in many industries because they offer various benefits.

You can use a plasma cutting table on a variety of metals, but this depends on the project. You can use a plasma cutter to cut a wide range of metals that have different thicknesses like aluminum, stainless steel, and copper with the thickness of at least 2.5”. They function with a lot of efficiency and can even cut up to 200” per minute.

You don’t need to have a lot of knowledge to operate a CNC plasma cutting table. In the past, a plasma table was limited to large businesses that could afford to purchase it. The good news is that recent advances in technology have brought in faster cutting machines that smaller businesses can use. Some plasma cutting tables are easy to use and one person can easily handle and operate the entire process.

Precision cutting is a major benefit of a plasma table, especially when it comes to cutting different sizes, shapes, and angles consistently with sheet metal. Some plasma tables have automatic height detection so that they can provide high quality and accurate cuts without any variations. Even better. A plasma table is faster than standard and traditional torches.

Above all, purchasing a plasma cutting table is cost effective. You can no longer waste materials and may take a lot out of the material sheets when you use a plasma cutting table. Another good thing is that it’s easy to set up your project into an effective grid so that the cutting table can precisely utilize small amounts of materials. In this way, you can decrease waste and even get more money from each sheet of material. Also, because the cutting process is more effective and efficient, you can lower the need of using more labor. This can also improve the bottom lines of your business over time.